Millpilot

Is your grinding process efficient enough?

MILLPILOT gets the most out of it and raises the output

Benefits at a glance

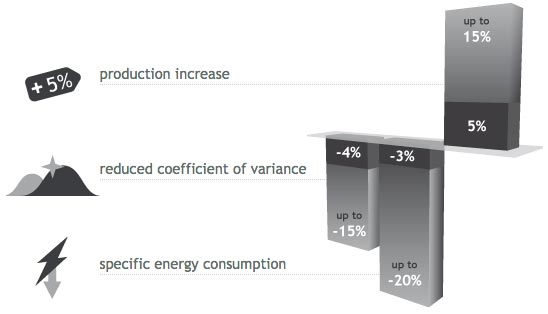

- more energy efficiency

- increase in production

- improved product fineness

- less wear

- higher facility availability

- reduced maintenance costs

Predictive control of grinding facilities

MILLPILOT controls closed grinding circuits—fully automated. If required, without operator. One system is able to operate up to four mills at the same time, thus increasing your facility’s availability by preventing overfilling and similar failures.

The consistent and optimal fill level ensures smooth and stable operation, leading to significantly less wear and a more homogeneous product. Additionally, the output increases and the power consumption drops.

MILLPILOT can be integrated into every automation system—it is simply plugged in via a standard OPC interface. With your previous control system on standby you can activate it at any time.

The new “auto adaptive” mechanism automatically and independently determines and adjusts the ideal filling level to always ensure optimal mill operation.

The modular concept allows you to choose the functions you need.

MILLPILOT offers modules for the control groups shown on the right.

If desired—thanks to our flexible system—additional modules can be developed and easily integrated at any time.

Benefit from MILLPILOT

- unattended operation

- auto adjustment

- ready-to-use modules

- fully automatic

- up to 4 mills (per system)

- fast commissioning

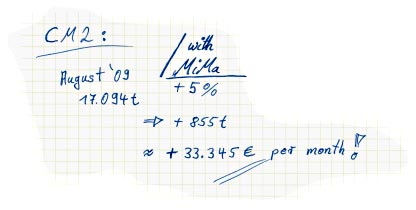

- return of investment in less than 1 year

- low investment costs

MILLPILOTs range of application

- vertical mills

- ball mills

- roller press

- separator / fineness

- hot gas generator

- water injection

- ventilation

Measured benefits

We guarantee to get the most out of your grinding equipment!

Get to know the advantages of using a modern control system.

Request your personal offer.