Smartfill (Coal)

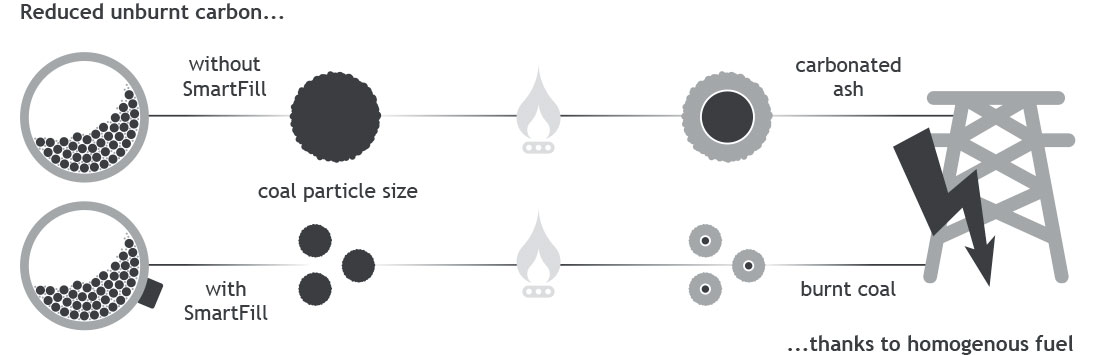

Are you looking to reduce your levels of unburnt carbon? SMARTFILL puts key information at your fingertips. That’s your key to success!

A homogenous degree of fineness is vital to ensure optimum combustion properties for your coal. SMARTFILL—a fail-safe, high-precision fill-level and temperature measurement system for ball mills—has been developed to help you achieve this.

For the first time ever, you can now accurately measure the most important grinding parameter: fill level. Since it is not possible to measure this key parameter directly, measurements need to be taken on the basis of acoustics or vibrations. Previous measuring methods, such as microphones, have a number of obvious disadvantages that mean they are wholly unsuitable for achieving the exacting standards required by today’s industrial producers; even measuring the drive current does not give accurate enough results.

How does SMARTFILL improve your energy efficiency?

Accurate measurements allow you to control the mill, meaning you can maintain an optimum fill-level at all times. Consequently, the mill’s operation is stable and regular, resulting in a much more uniform coal output.

What is more, setting the optimum fill-level reduces wear to the balls and mill shell. You can avoid overfilling the mill, thereby improving the plant’s uptime; this, in turn, leads to increased levels of production. Irrespective of the type of control system used, SMARTFILL allows you to make the right decisions at the right time. Thanks to SMARTFILL, you can now act rather than react when controlling your mill.

How does SMARTFILL work?

SMARTFILL measures the mechanical vibrations of the mill using up to three different types of sensor, all of which are positioned directly on the mill shell. The measurement information is transmitted wirelessly to the relevant testing instrument, and can be connected to your PLC (4—20mA).

What type of mills is SMARTFILL suitable for?

SMARTFILL (Coal) is suitable for use in a variety of different types of ball mills, including (air-swept) tube mills, centre discharge mills and SAG mills. It can also be used irrespective of the type of lining (steel/rubber), grinding media (balls/cylpebs) or grinding process (wet/dry).

High-precision fill-level measurement

- easy installation

- zero crosstalk

- unoccupied frequency band

- virtually maintenance-free

- process interface (4—20 mA)

- up to 3 sensors of your choice

- self-powered (On Mill Unit)

- type tested: IP65 / Atex