Gastemp flow

Precise & reliable acoustic measurement

THAT‘S WHAT WE CALL

THE KIMA PROCESS:

-

short response times

-

flexible areas of application

-

high accuracy

-

ensured new process stability

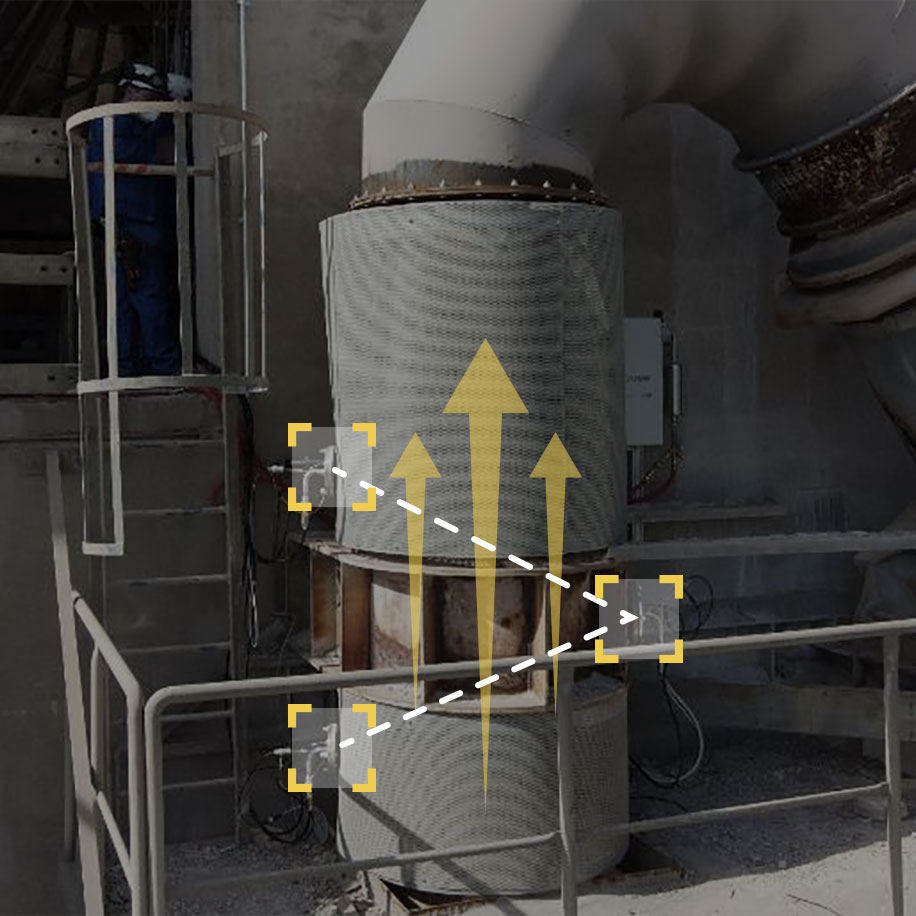

Gastemp: areas of application

Due to the fast reaction and the precise temperature measurement there are many measurement positions.

Applications:

- 1) Down comer flow + temperature

- 2) Calciner exit temperature

- 3) Tertiary air flow + temperature

- 4) Flue gas stack flow + temperature

- 5) Bypass/WHR flow + temperature

- 6) Secondary air temperature

as well as VRM/mill outlet flow + temperature

and more on demand…

Acoustic Gas Temperature

plus Flow Measurement

The system measures the gas temperature and speed of flow as an average along a path through a duct. The speed of sound is measured against -and in the direction of the gas flow. Using the cross section of the duct, the gas flow can be converted to the volume flow. As the gas temperature is measured also, the correct gas volume is calculated. (Enthalpy measurement)

Acoustic measurement of gas temperatures

The efficiency of many processes in chemical, thermal and process engineering is determined by gas temperatures. In order to optimise these processes by means of closed-loop controls, the gas temperature needs to be measured promptly and precisely. The “classical” thermo couple method reaches thermal equilibrium with the gas to be measured with a long delay and is interferred by heat radiating surfaces.

In contrast, the speed of sound in gases depends on the gas temperature only. The newly developed ceramic sensing element measures the speed of sound in gas quickly and very precisely, and thus directly determines the gas temperature with the same accuracy and high speed (500—1 000 msec).

Application examples

- secondary air

- tertiary air

- clinker cooler

- exhaust

- calciner